Includes

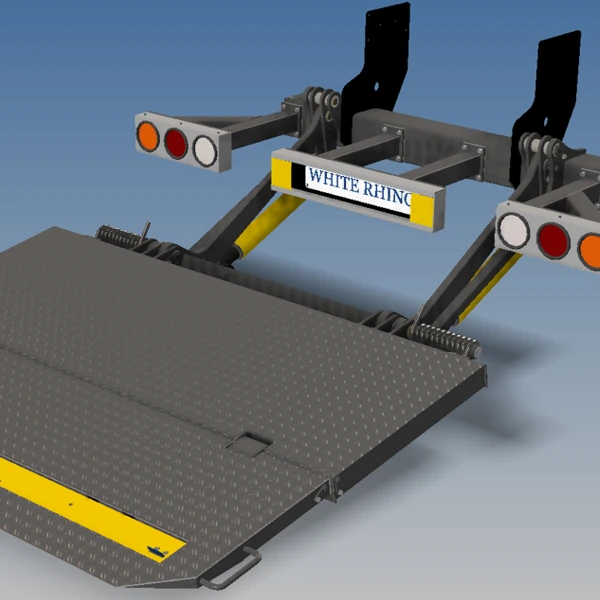

• Manual center stopper,

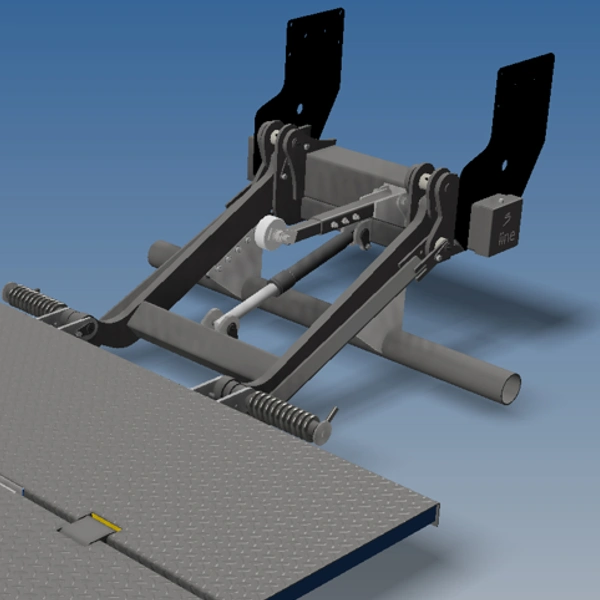

• Centre hydraulic cylinder,

• 12-month Warranty, based on 3-month inspections,

• LMI Certificate valid for 1 year.

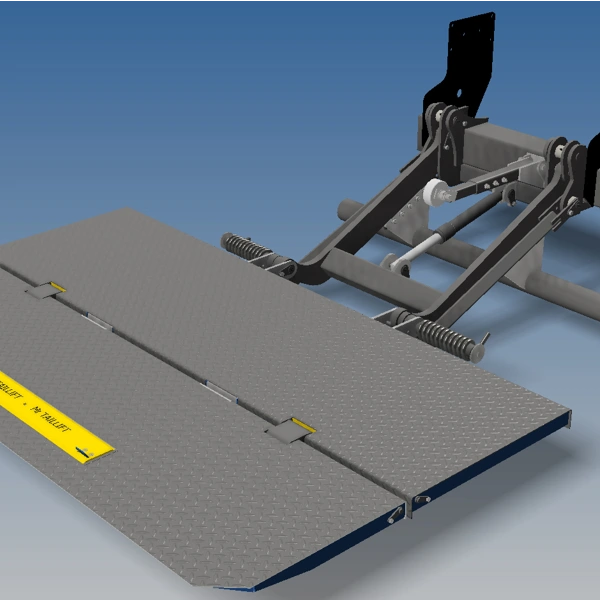

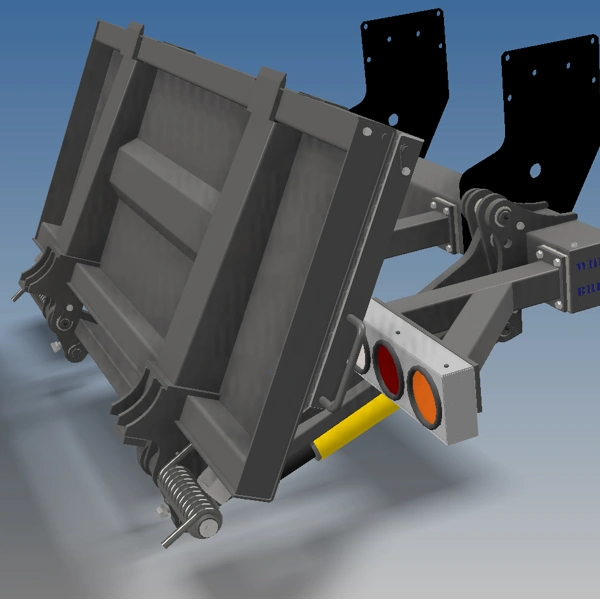

PLATFROM

• Full steel folding platform.

CHARACTERISTICS

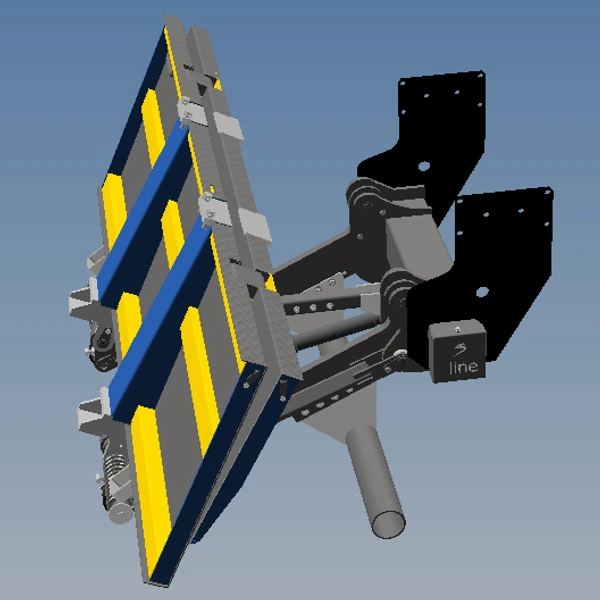

• Torsion bar for easy opening and closing of platform,

• At ground level, platform will tilt automatically,

• External mounted control box,

• Electro-hydraulic power pack (12v or 24v)

• Cylinder shafts in hard-chromed stainless steel,

• Cylinders equipped with rubber gaiters and lubrication,

• Electrical controls without sensitive electronic components,

• Thermo switch on motor,

• Complete steel tail lift at a weight of only 350kg.

OPTIONAL EXTRAS ON REQUEST

• Battery guard

• Cycle counter

• Protection PLUS frame

• KTL finish platform

• Limit switch

• Toggle switch

• Wonder lead.